Beer Taps

What are beer taps?

Beer taps, also known as tap faucets, are an essential component of any draft system in a bar, restaurant, or brewery. They are used to dispense beer or other beverages from a keg into a glass. They regulate the flow of the beverage, ensuring the correct amount is poured into the glass. The operation of a beer tap is relatively simple: by opening the tap, the pressure in the keg is released, allowing the beer or beverage to flow through the lines into the tap and finally into the glass. Closing the tap stops the flow.

There are different types of beer taps, selected depending on the need and type of beverage. For instance, beer taps come in various diameters, materials, and designs. The type of cooling and tapping technique can also vary. Overall, beer taps are an indispensable tool for dispensing beer and other beverages and play a crucial role in the quality of the pour.

How does a compensator beer tap work?

Compensator beer taps are special beer taps used in the hospitality industry to ensure consistent beer dispensing and storage. They are designed to balance the pressure in the system, resulting in an optimal foam head and perfect taste. There are various types of compensator beer taps that differ in their construction and functionality to meet the diverse requirements of the hospitality industry. A piston beer tap, also known as a compensator beer tap, features different settings. It widens slightly towards the tap outlet, ensuring that the beer gradually relaxes and doesn’t lose carbonation. It is important that a constant pressure of at least 1.8 bar is maintained in the beer tap.

What should you consider when buying a beer tap?

When buying a beer tap, there are several important points to consider. First, pay attention to the quality of the material, as a high-quality beer tap is more durable and offers better performance. It is also important to choose the appropriate size of the beer tap for the respective draft system to ensure smooth tapping. Furthermore, compatibility with the specific keg should be checked to achieve optimal results. Another crucial aspect is the ease of cleaning the beer tap, as regular cleaning is essential for hygiene. By considering these points, you can ensure that you purchase a high-quality and suitable beer tap.

Proper cleaning and maintenance of beer taps

To ensure that your beer taps always function flawlessly and the beverages remain of high quality, regular cleaning and maintenance are essential. After each use, the beer tap should be thoroughly rinsed with clear water to remove any residue. Additionally, it is recommended to regularly disassemble the beer tap and clean it with special cleaning agents. All parts of the beer tap should be thoroughly cleaned and disinfected. Make sure that no cleaning residues are left behind, as they could affect the taste of the beverage. Regular maintenance and care extend the lifespan of your beer tap and ensure flawless operation, allowing you to serve freshly tapped beverages of the best quality to your guests.

Tips and tricks for using beer taps

When it comes to tapping beer, there are several important tips and tricks to achieve a perfect result. Firstly, it is important to regularly clean the beer tap to avoid contamination and maintain the quality of the beer. Additionally, the beer tap should be handled correctly by holding the glass at an angle and pouring slowly to avoid excessive foam. It is also advisable to regularly check the pressure in the keg to ensure the beer flows optimally. Another important tip is to properly close the beer tap after use to prevent beer from leaking and to ensure hygiene. With these tips, nothing stands in the way of a perfectly tapped beer.

Functions of a beer tap

Dispensing beverages: The primary function of a beer tap is to draw beer or other beverages from a keg or line and fill glasses or mugs.

Flow regulation: The beer tap allows the operator to control the flow of the beer. By opening and closing the tap, the amount of beer dispensed can be precisely regulated.

Foam control: A well-designed beer tap helps avoid excessive foam when dispensing, which is important for the quality of the served beer.

Hygiene: The beer tap is designed to remain hygienic and prevent contamination of the beer. Many models feature special materials or coatings with antibacterial properties.

Temperature maintenance: Some modern beer taps are equipped with cooling systems to keep the beer at the optimal serving temperature.

Construction of a Beer Tap

A typical beer tap consists of several components:

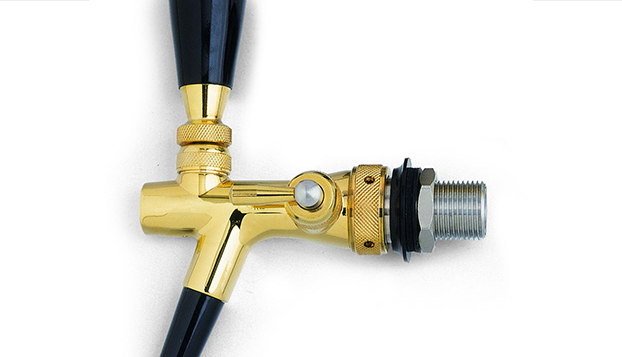

Tap Body: The main part of the tap, usually made of metal (often stainless steel). It contains the mechanism for controlling the flow of beer.

Tap Valve: The valve inside the tap regulates the flow of beer. It opens when the tap is activated and closes when it is released.

Handle: The handle is operated by the user to open or close the tap. It can come in various shapes and designs.

Seals and O-Rings: These parts ensure that the tap closes tightly and prevents beer from leaking when not in use.

Connections: When connecting a beer tap, ensure it is sealed properly, compatible, securely fastened, easy to handle, and clean, to ensure smooth operation.

Cleaning of Beer Taps:

- Cleaning Agents: Special cleaning agents for beer lines and taps (e.g., alkaline or acidic cleaners).

- Water: Warm water to dilute the cleaning agent.

- Bucket or Container: For mixing the cleaning solution.

- Brushes: Soft brushes for manually cleaning hard-to-reach areas.

- Cloths or Rags: For wiping and drying.

- Protective Gear: Gloves and possibly safety goggles.

Step-by-Step Cleaning Instructions

Preparation

- Turn off the draft system and disconnect the beer tap from the beer line.

- Ensure all necessary materials are ready.

Prepare Cleaning Solution

- Mix the cleaning agent according to the manufacturer's instructions with warm water in a bucket or container.

Disassemble the Tap

- Remove the handle of the beer tap, if possible, to access the internal components.

- Lay out the parts in the correct order for easy reassembly later.

Manual Cleaning

- Use a soft brush to remove any visible residue inside the tap.

- Dip the brush in the cleaning solution and thoroughly clean all parts of the tap, including seals and O-rings.

Rinse

- Rinse all parts thoroughly with clear water to ensure no cleaning agent residues remain.

Disinfection (Optional)

- In some cases, it may be advisable to apply a disinfection solution to ensure all bacteria are killed.

Maintenance:

- Visual Inspection: Regularly check the beer tap for visible damage, cracks, or corrosion. Also, look for leaks, which could indicate defective seals or valves.

- Function Test: Operate the tap to ensure it opens and closes smoothly. Check whether the beer flow is even and if there are any splashes or irregular flow.

- Regular Cleaning: Clean the beer tap regularly (ideally after every keg change or at least once a week) to remove residues and deposits.

- Use Cleaning Solution: Use special cleaning agents for beer lines and taps to ensure all residues are removed.

- Seals and O-Rings: Check the seals and O-rings for wear or damage. These parts should be replaced if necessary to prevent leaks.

- Lubrication: Use suitable food-grade or beer-safe lubricants for moving parts to ensure smooth operation.

Materials:

Tap Body:

The main part of the beer tap, typically made of stainless steel or chrome-plated brass. These materials are corrosion-resistant and easy to clean.

Tap Valve:

The valve inside the tap that controls the flow of beer. It opens when the tap is activated and closes when released.

Handle:

The lever or handle that the user operates to control the tap. It can be available in various shapes and designs and is often ergonomically designed.

Seals and O-Rings:

These parts ensure the tap closes tightly and prevent leaks. They are usually made of rubber or silicone and should be regularly checked for wear.

Beer Connection:

The connection for the beer line, which channels the beer from the keg to the tap. This connection can vary depending on the system (e.g., threaded or bayonet connection).

Air or Pressure Valve (Optional):

Some beer taps have an additional valve to regulate the pressure in the system, ensuring even beer flow.

Cleaning Connection (Optional):

Many modern beer taps have a cleaning connection that allows for easy cleaning and disinfection of the tap.

Drip Tray (Optional):

A drip tray can be placed under the tap to catch excess beer and keep the workspace clean.

Manufacturing:

Material Selection:

- Stainless Steel or Brass: Most beer taps are made from corrosion-resistant materials like stainless steel or chrome-plated brass. These materials are hygienic and durable.

Shaping:

- Casting: For brass parts, a casting process is often used, where the molten metal is poured into a mold.

- Machining: Stainless steel parts are often shaped using CNC (Computer Numerical Control) machining to achieve precise dimensions and surfaces.

Milling and Turning:

After casting or machining, the parts are milled and turned to achieve the desired shapes and dimensions. This includes creating threads, holes, and other specific features.

Surface Treatment:

- Polishing: To ensure a smooth surface, the parts are polished. This not only improves the appearance but also makes cleaning easier.

- Chrome Plating or Coating: Brass parts may be chrome-plated to prevent corrosion and increase durability.

Component Assembly:

The various parts of the beer tap (tap body, valve, seals, etc.) are assembled. It is important that all seals are correctly placed to avoid leaks.

Quality Control:

Each beer tap undergoes strict quality control to ensure it meets the required standards. This includes testing for tightness and functionality.

Areas of Application

Gastronomy

- Pubs and Bars: Taps are a central element in pubs and bars, where they are used to pour beer and other beverages.

- Restaurants: Many restaurants offer draft beer, and taps are necessary to serve these drinks.

Breweries

- Taps are used in breweries to provide freshly brewed beer for tastings or bottling. They are often part of the production process.

Events and Festivals

- Portable taps are used at beer festivals, trade shows, or other events with mobile bars to efficiently serve a large quantity of beverages.

Home Brewing

- Hobby brewers use taps in their homebrew setups to fill or serve their homemade beer.

Catering and Events

- Catering services use taps at events such as weddings or corporate parties to offer draft beer or other beverages.

Sports Events

- In stadiums and sports arenas, taps are used to quickly serve drinks to fans.

Trade Shows and Exhibitions

- At trade shows, companies can use taps to present their products (e.g., new beer varieties) and offer tastings.

Beverage Variety

- In addition to beer, taps can also be used for other beverages such as cider, lemonade, or cocktails, provided they are designed accordingly.

Combination with Cooling Systems

- In many modern bars, taps are part of a cooling system that ensures beverages are served at the optimal temperature.

Manufacturers

Celli S.p.A.

- Origin: Italy

- Description: Celli is one of the leading manufacturers of beverage dispensing systems worldwide. Founded in 1974, the company specializes in the development and production of taps, dispensing systems, and other beverage dispensing solutions. Celli offers a wide range of products, including solutions for beer, water, wine, soft drinks, and other beverages. The company emphasizes innovation, sustainability, and design to provide both functional and aesthetically pleasing products.

Vinservice

- Origin: Italy

- Description: Vinservice is an Italian company specializing in the manufacture of beverage dispensing systems, particularly for beer, wine, and soft drinks. Vinservice offers innovative solutions for the dispensing industry, focusing on precision and efficiency. They provide a variety of taps and accessories suitable for different types of beverages and applications.

- Example Product: Standard Chrome-Plated Brass Tap 5/8x35 mm with Compensator

- Material: This tap is made of chrome-plated brass, a popular choice in the dispensing industry due to its durability, longevity, and corrosion resistance. The chrome plating also provides an aesthetic appearance and makes cleaning easier.

- Size: The dimensions 5/8x35 mm refer to the diameter and length of the connector, which is typically standardized to be compatible with most beverage hoses and dispensing systems.

- Compensator: The integrated compensator is an important feature that allows for regulating the pressure and flow rate of the beverage. This is particularly crucial when dispensing beer to control foam formation and ensure even pouring.

- Summary: This tap is popular for its reliability, ease of use, and ability to regulate dispensing precisely. It is commonly used in bars, restaurants, and breweries that have high standards for the quality and consistency of their beverages.

Raffeiner GmbH

- Origin: Germany

- Description: Raffeiner GmbH is a German company that has been manufacturing taps and dispensing systems for many years. It is known for its robust and reliable products, which are highly regarded in the gastronomy and beverage industry. Raffeiner emphasizes the quality and durability of its products and offers customized solutions for its customers.

Tof Srl

- Origin: Italy

- Description: Tof is an Italian manufacturer of beverage dispensing systems and accessories, known for its high-quality and innovative products. Tof offers a wide range of taps and dispensing systems suitable for various beverage types. The company has made a name for itself through its technology and product design.

Bevco

- Origin: USA

- Description: Bevco is an American company that offers dispensing solutions for the beverage industry. They are known for their high-quality taps, dispensing systems, and beverage dispensers. Bevco provides customized solutions that meet the specific requirements of their customers, emphasizing efficiency and user-friendliness in their products.

Felom

- Origin: Italy

- Description: Felom is another Italian manufacturer of dispensing systems and accessories. The company offers a wide range of products, including taps used in the gastronomy and beverage industry. Felom is known for its high-quality products and excellent customer service.

These companies play an important role in the beverage industry, supplying restaurateurs worldwide with high-quality and durable dispensing systems. Their products are designed to meet the demands of bars, restaurants, and other hospitality venues while offering high functionality and aesthetics.

Advantages of Taps

- Freshness: Taps allow beverages, especially freshly brewed beer, to be served directly from the keg, enhancing the taste experience.

- Efficiency: They enable quick and easy dispensing of beverages, which is especially important in busy bars and restaurants.

- Control Over Dispensing: Taps allow for precise control over the amount of beverage dispensed, helping to minimize waste.

- Versatility: Taps can be used for various beverages, including beer, cider, lemonade, and cocktails.

- Integration with Cooling Systems: Many modern taps are part of a cooling system that ensures beverages are served at the optimal temperature.

- Ease of Cleaning: Many models feature integrated cleaning connectors that ensure easy maintenance and hygiene.

Disadvantages of Taps

- Cost: The cost of purchasing high-quality taps and related systems can be high, particularly for commercial applications.

- Maintenance Effort: Regular maintenance and cleaning are required to ensure the quality of dispensed beverages and to avoid issues like clogging or leaks.

- Space Requirements: In small bars or restaurants, space for installing taps and associated kegs can be limited.

- Technical Issues: Like any technical device, taps can experience problems (e.g., pressure issues) that can disrupt operations.

- Staff Training: Staff must be trained to ensure proper use of taps and to ensure they are used efficiently.

Conclusion on Taps

Taps are an indispensable element in the hospitality industry and at events that offer beverages from kegs. They offer numerous advantages, including the ability to efficiently and controllably serve fresh drinks. The versatility of taps allows for serving different types of beverages, making them a practical solution for bars, restaurants, and events.

However, some disadvantages should also be considered. The initial cost can be high, and regular maintenance is required to ensure optimal functionality and hygiene. Additionally, space requirements in smaller establishments can be a challenge.

Overall, the advantages of taps in most commercial applications outweigh the disadvantages. They contribute to an improved customer experience and enable efficient service. For operators of hospitality businesses, investing in high-quality taps is often worthwhile to optimize both quality and service.